FOB Price:US $ 20,000 - 600,000 / Set | Get Latest Price

Min.Order Quantity:1 Set/Sets

Supply Ability:5 Set/Sets per Month

Port:China

Payment Terms:L/C,D/P,T/T,Western Union

Quick Details

- Condition: New

- Capacity: 396000 capsule/hours

- Control Mode: Full Automatic

- Place of Origin: Liaoning, China (Mainland)

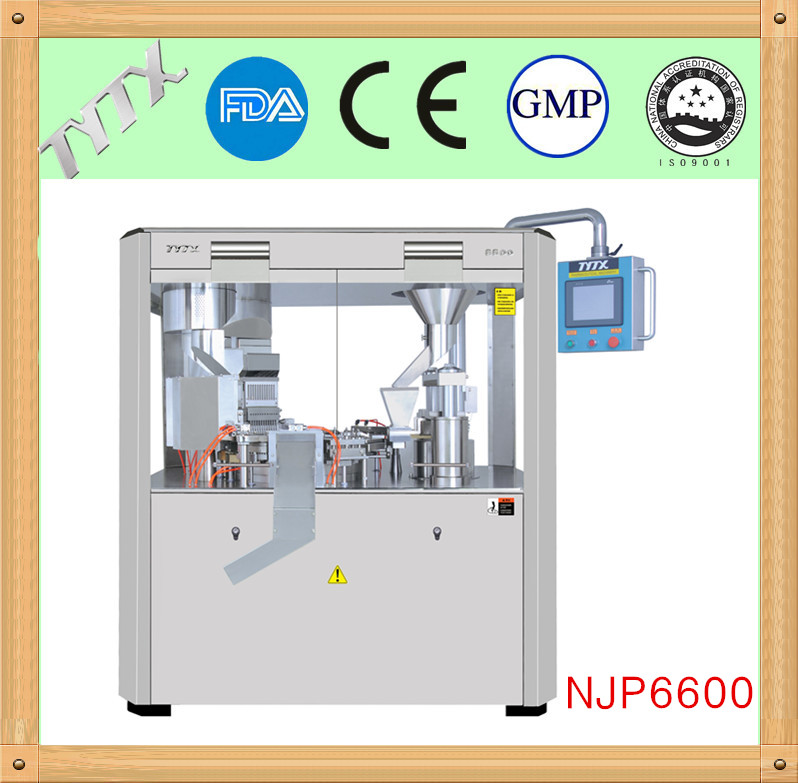

- Brand Name: TYJX

- Model Number: NJP6600

- Dimension(L*W*H): 2000*1600*2200

- Weight: 4000KG

- Certification: CE\ FDA \ ISO9001

- Warranty: one year

- After-sales Service Provided: Engineers available to service machinery overseas

- Type: Filling Equipment

- material: stainless stell 304 & 316

- Application: Capsule filling

Packaging & Delivery

| Packaging Details: |

Export Worthy Package |

| Delivery Detail: |

One and a half month |

Specifications

Max. capacity: 396000 capsules/h with filling rate up to 99% suitable for capsule size 00 to Size 5

pellet device

For the automatic capsule filling machine we are the first who adopt the automatic control systerm for the powder loading process,reducing the manual operation ,meeting with the GMP requirement and CE approved .![]()

Pharmaceutical, medicine, and chemicals.

![]()

This is a newly created full-automatic closed intermittent capsule filling machine with multiple tamping stations.It completes the following process:feeding capsule,detaching capsule, filling, ejecting defective capsule,closing capsule, discharging finished capsule automatically.

This machine can be equipped with vacuum loader for capsules and powder, which reduces the wokers cost, and all the operation is conducted on the touch screen, which is a highly automation machine of water, electricity and pneumatic.

- Independent control system , which make the main motor and the mechanical systerm is not mutual interference each other .

- There is big resistance when the filling pole running up and down .to reducing this resistance ,we adopt counterweight assistant .guaranteeing the machine running safely.

- Conditioning site adopt clear handspike enter into the lower module Directly and with the air . to make the power which is in the upper and lower module can be cleared in time . avoide the left powder influence the next station .

- To increase the transmission torquemoment ,increase the diameter of the principal axis , to make sure the transmission more stablely and increasing load resistor ability.

- Die hole array with Back and forth derangement ,which is greatly increase the powder filling precision ,make sure the filling capacity is more exactly .

- Adopt multiholedoctor , make the powder can be dispersed equably on the dosing disc , which is more favorable for the capacity exactly .

- New structure twelve state totally closed batch type rotating floor .upper and lower module uni-directional running is safe and reliable . totally closed structure make the products prevent the lubrication oil from pollution .according with GMP.

- Simplify quibcunx leveling structure and upper base . which is convince to cleaning the spread powder and increasing the work efficiency .

- Batch gas auxiliary system for exhausting capsule , avoid exhaust long time and without a break .

- Accurate orientation, Capsule vacuum positioned mechanism to make the capsule upload percentage over 99%

- Freely adjusting dosage, easy speed selection and closed capsule length adjustment.

- PLC program control panel with LCD.Touch screen operation, and monitoring function.

- Displaying in-time speed and accumulative output.

- Auto-trouble shooting, lack of material, lack of capsule, block in material channel and other mechanical trouble, make alarm and stop automatically.

- Electrical Appliance control system approved to CE, and international standard.

- Quick and accurate change part set-up, easy to remove rotary table and ring carrier assembly.

- Fully enclosed dosing stations and rotating table for integration of the whole capsule filling plants.

- Working station cam runs under the good lubricating condition, extends the operating life of change parts. cam is made by USA HASS CNC and Germany DMG machine.

- Alarm list

a.Alarm when doors and windows are opened

b. Main motor inverter alarm

c. Feeding motor overload alarm

d. Lock of capsules alarm

e. Lcok of powder alarm

f.Scram alarm

g. Off phase and phase sequence alarm protection

h.Vacuum overload alarm

i.Dust collector overload alarm