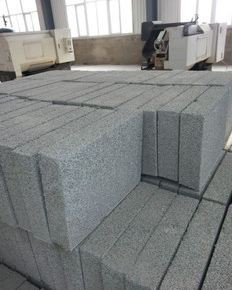

Foam insulation board is a kind of high performance inorganic heat preservation material, it is a kind of porous lightweight high-performance cover plate level cultural relics, is by a variety of inorganic gelling material and modifying agent, foaming agent and other additives by mixing system, curing system, cutting system and other equipment made of a low thermal conductivity, thermal insulation performance is good, high temperature resistant, aging resistant, A1 class non-combustible inorganic heat preservation material, cement foam insulation board can be widely used in building exterior wall thermal insulation system.

1, the green environmental protection

Green without excitant and harmful gas release;Mineral wool type of floater damage to human skin and respiratory tract;Produce smoke toxicity for security level (AQ1) production and construction installation process with no harmful gas and waste emissions, less carbon emissions;There is no repeat heat preservation demolition waste on the environment pollution.

2, refractory high temperature resistant

Cement foam insulation board refractory can reach more than 1000 degrees Celsius temperature, combustion performance level for A1, non-combustible material, fire safety performance is superior.

3, insulating Gao Baowen stays

Cement foam insulation board obturator rate is greater than 97%, high obturator rate make the air convection heat transfer is significantly reduced, cement foam insulation board minimum thermal conductivity can reach 0.045 W/m * k, with polystyrene board the coefficient of thermal conductivity of basic quite, can meet the need of building thermal insulation.

4, bibulous rate is low

Cement foam insulation board bibulous rate is low, ensure that the product will not mildew in damp environment, will not affect the thermal insulation performance, guarantee the security and durability of the product.

5, light weight, high strength

Cement foam insulation board has solved the material of low density and high strength paradoxical technical problems, reached a relatively uniform.Density of 180 kg/m3, the compressive strength of 0.2 MPa above, to satisfy the transportation and the requirement of strength in the process of the engineering application.

6, long life, resistance to aging

General organic insulation board system of life for 25 years, life expectancy due thick building insulation to twice or three times to do;Cement foam insulation board the life span of more than 50 years, and the life of the building can be synchronized, building a single thermal insulation construction for life.

Foam insulation board is a kind of high performance inorganic heat preservation material, it is a kind of porous lightweight high-performance cover plate level cultural relics, is by a variety of inorganic gelling material and modifying agent, foaming agent and other additives by mixing system, curing system, cutting system and other equipment made of a low thermal conductivity, thermal insulation performance is good, high temperature resistant, aging resistant, A1 class non-combustible inorganic heat preservation material, cement foam insulation board can be widely used in building exterior wall thermal insulation system.

1, the green environmental protection

Green without excitant and harmful gas release;Mineral wool type of floater damage to human skin and respiratory tract;Produce smoke toxicity for security level (AQ1) production and construction installation process with no harmful gas and waste emissions, less carbon emissions;There is no repeat heat preservation demolition waste on the environment pollution.

2, refractory high temperature resistant

Cement foam insulation board refractory can reach more than 1000 degrees Celsius temperature, combustion performance level for A1, non-combustible material, fire safety performance is superior.

3, insulating Gao Baowen stays

Cement foam insulation board obturator rate is greater than 97%, high obturator rate make the air convection heat transfer is significantly reduced, cement foam insulation board minimum thermal conductivity can reach 0.045 W/m * k, with polystyrene board the coefficient of thermal conductivity of basic quite, can meet the need of building thermal insulation.

4, bibulous rate is low

Cement foam insulation board bibulous rate is low, ensure that the product will not mildew in damp environment, will not affect the thermal insulation performance, guarantee the security and durability of the product.

5, light weight, high strength

Cement foam insulation board has solved the material of low density and high strength paradoxical technical problems, reached a relatively uniform.Density of 180 kg/m3, the compressive strength of 0.2 MPa above, to satisfy the transportation and the requirement of strength in the process of the engineering application.

6, long life, resistance to aging

General organic insulation board system of life for 25 years, life expectancy due thick building insulation to twice or three times to do;Cement foam insulation board the life span of more than 50 years, and the life of the building can be synchronized, building a single thermal insulation construction for life.