LSM1150 vertical fine powder grinding mill is an ideal equipment of milling industry, incorporate crush,milling, grading, conveying into an organic whole.Widely used in Caco, speckstone,ferrous powder, conductex, bentonite, molybdenum,limestone,tabular spar,dolomite,mica,superfine cement,power,metallurgy,chemical industry etc. used for grind massive,granular and floury raw material into required powdered material.

Main structure:

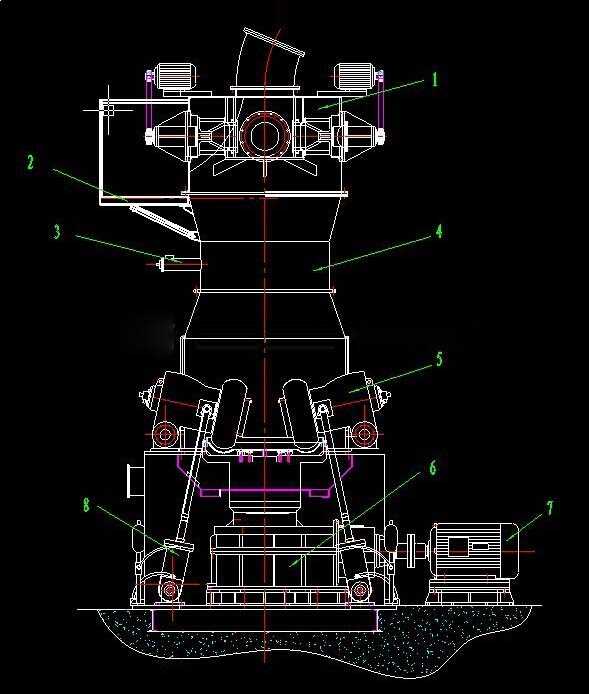

This mill is composed of powder concentrator, grinding device, grinding disc device, pressure device, reducer, electric motor, air blower, shell etc.

Operating principle:

the electric motor drive the grinding disc device rotate through the reducer, the material move to the edge of the grinding disc under centrifugal force, rolled by the roller and crushed when go through the ring groove on the grinding disc. The crushed material go up by the jet stream on the edge of grinding disc, the bulky grain fall on the grinding disc directly. When the material in the jet stream through upper separator the coarse powder fall on the grinding disc from the cone re grinding under the action of rotating rotor, the qualified fine powder come out along with the airflow, the dust arrester installation collect it then be the product. It can be different granularity by adjust the separator.

Models and parameters:

|

Function

|

output

(Kg/h)

|

Crushing fineness

(d97/um)

|

mess size of feed(mm)

|

Power

(KW)

|

|

Model

|

|

JL900

|

1000-6000

|

2-40

|

0-20

|

320

|

|

JL1100

|

2000-12000

|

2-40

|

0-20

|

630

|

Output and physical chemical chart:

A:Vertical mill model:JL-900

|

Test item

|

|

Heavy super-fine CaCO3

|

|

Output/hour

|

ton

|

5.0~6.0

|

4.5~5.0

|

3.5 ~4.0

|

3.0 ~3.2

|

2.0~2.2

|

1.3 ~1.5

|

|

Specific surface area

|

cm2/g

|

8500±500

|

11000±500

|

14000±500

|

16000±500

|

18000±1000

|

20000±1000

|

|

325 Mesh residue

|

%

|

0.02

|

0.015

|

0.01

|

0.01

|

0.002

|

0

|

|

Smaller than 2μm content

|

%

|

23

|

32

|

40

|

46

|

53

|

60

|

|

Average particle size: d50

|

μm

|

8.1

|

5.2

|

3.0

|

2.4

|

1.8

|

1.3

|

|

Market common name

|

mesh

|

400

|

600

|

800

|

1000

|

1500

|

2000

|

|

Particle size distribution:d97

|

μm

|

35

|

23

|

20

|

15

|

10

|

8.5

|

|

Largest particle size

|

μm

|

58

|

48

|

38

|

31

|

23

|

18

|

|

Close apparent specific gravity

|

g/cm3

|

1.25

|

1.18

|

1.06

|

0.90

|

0.85

|

0.74

|

|

Loose apparent specific gravity

|

g/cm3

|

0.53

|

0.45

|

0.38

|

0.34

|

0.32

|

0.28

|

|

Moisture

|

%

|

Under 0.4

|

Under 0.4

|

Under 0.4

|

Under 0.4

|

Under 0.4

|

Under 0.4

|

|

Sediment volume

|

1 hour later (C.C)

|

18

|

23

|

26

|

32

|

42

|

50

|

|

Energy consumption (mill,blower,classifier)

|

kw/ton

|

49

|

52

|

61

|

70

|

98

|

112

|

B:Vertical mill model:JL-1100

|

Test item

|

|

Heavy super-fine CaCO3

|

|

Output/hour

|

ton

|

10.0~10.5

|

9.0~9.5

|

8.0 ~9.0

|

6.0 ~6.5

|

4.0~4.5

|

3.0 ~3.5

|

|

Specific surface area

|

cm2/g

|

8500±500

|

11000±500

|

14000±500

|

16000±500

|

18000±1000

|

20000±1000

|

|

325 Mesh residues

|

%

|

0.02

|

0.015

|

0.015

|

0.01

|

0.002

|

0

|

|

Smaller than 2μm content

|

%

|

23

|

32

|

40

|

46

|

53

|

60

|

|

Average particle size: d50

|

μm

|

8.1

|

5.2

|

3.0

|

2.4

|

1.8

|

1.3

|

|

Market common name

|

mesh

|

400

|

600

|

800

|

1000

|

1500

|

2000

|

|

Particle size distribution:d97

|

μm

|

35

|

23

|

20

|

15

|

10

|

8.5

|

|

Largest particle size

|

μm

|

58

|

48

|

38

|

31

|

23

|

18

|

|

Close apparent specific gravity

|

g/cm3

|

1.25

|

1.18

|

1.06

|

0.90

|

0.85

|

0.74

|

|

Loose apparent specific gravity

|

g/cm3

|

0.53

|

0.45

|

0.38

|

0.34

|

0.32

|

0.28

|

|

Moisture

|

%

|

Under 0.4

|

Under 0.4

|

Under 0.4

|

Under 0.4

|

Under

0.4

|

Under

0.4

|

|

Sediment volume

|

1 hour later (C.C)

|

18

|

23

|

26

|

32

|

42

|

50

|

|

Energy consumption (mill,blower,classifier)

|

kw/ton

|

45

|

48

|

55

|

63

|

89

|

101

|

Main characters:

Low investemet cost

Incorporate crushing, grinding, classifying, conveying as an organic whole, simple system, compact layout, cover about 50% area of ball mill system, meanwhile can open arranged, so it can largely reduce investment cost.

Low operating cost

High efficiency grinding: the roller grinding directly on the grinding disc, grind the material, low energy consumption, save energy about 30-40% compare to the ball mill system.

Less wear

Since the grinding roller not direct contact the gringing disc, also the roller and the liner plate are made of excellent material, so its lifetime is ling, less wear.

Simple operation:

Reliable operation, automatic control system, remote control, simple operation. Prevent the roll ring and liner plate direct contact the device, avoid destructive impact and strenuous vibration.

Steady product quality

Since the material staying time in the mill is short it is easy to control the product fineness and test the chemical composition, so it can decrease re grinding stabilize the product quality.

Convenient maintenance

Change roll ring and liner plate through examine and repair the cylinder and flip boom, convenient and speedily, reduce losses of downtime.

Meet the environmental protection

Less vibration, low noice, whole leakproof equipment, operate under negative pressure, no dust overflow, clean environment, meet the environmental protection requirement.

Structure:

1--grading machine

2--grading machine maintenance platform

3--feed screw conveyer

4--connecting section

5--grinding roller

6--reducer of vertical mill

7--main electric motor

8--fluid cylinder