Specification for concentric tube heat exchanger

We produce series of oil coolers for marine or river boat engine, hydraulic system cooling including the following series

1. DC Heat Exchangers

2. Engine & Transmission Oil Coolers

3. Hydraulic Oil Coolers

4. Exhausted Air to Water Intercoolers

5. Marine Heat Exchangers

6. Fuel Coolers

7. After Coolers

Features of concentric tube heat exchanger:

With corrugated tubes, this marine heat exchanger ensures high viscosity oil with good flow velocity inside of the unit.

This features made this marine heat exchanger efficient and cost effective on water to oil cooling system.

Performance data of Marine heat exchangers

Typical examples of heat exchangers fitted to marine transmissions with an oil inlet temperature of 80°C and a sea water temperature of 32°C.

| Type |

Sea water pipe |

Engine Water PipeHP |

Engine power |

| (mm) |

KW |

HP |

| DC 50 |

20 or 25 |

Rc 3 or 8" or 1 or 2" |

30 |

40 |

| DC 60 |

20 or 25 |

Rc 3 or 8" or 1 or 2" |

40 |

54 |

| DC 90 |

20 or 25 |

Rc 3 or 8" or 1 or 2" |

60 |

80 |

| DC120 |

20 or 25 |

Rc 3 or 8" or 1 or 2" |

80 |

107 |

| EC 80-E |

32 or 40 |

Rc 1 or 2" |

60 |

80 |

| EC100-E |

32 or 40 |

Rc 1 or 2" or 3 or 4" |

90 |

120 |

| EC120-E |

32 or 40 |

Rc 1 or 2" or 3 or 4" |

120 |

160 |

| EC140-E |

32 or 40 |

Rc 3 or 4" |

150 |

200 |

| FC100-E |

65 |

Rc 1" |

135 |

180 |

| FC120-E |

65 |

Rc 1" |

180 |

240 |

| FC140-E |

65 |

Rc 1" |

225 |

300 |

| FC160-E |

65 |

Rc 1" |

270 |

360 |

| FG100-E |

Rc 2 1 or 2" |

Rc 1 1 or 4" |

225 |

300 |

| FG120-E |

Rc 2 1 or 2" |

Rc 1 1 or 4" |

270 |

360 |

| FG140-E |

Rc 2 1 or 2" |

Rc 1 1 or 4" |

360 |

480 |

| GL140-E |

Rc 2" |

Rc 1 1 or 2" |

360 |

480 |

| GL180-E |

Rc 2" |

Rc 1 1 or 2" |

450 |

600 |

| GK190-E |

100 |

Rc 2" |

700 |

940 |

| GK250-E |

100 |

Rc 2" |

950 |

1270 |

| GK320-E |

100 |

Rc 2" |

1200 |

1608 |

| GL140-H |

Rc 1 1 or 2" |

Rc 2" |

180 |

240 |

| GL180-H |

Rc 1 1 or 2" |

Rc 2" |

250 |

335 |

| GL240-H |

Rc 1 1 or 2" |

Rc 2" |

320 |

428 |

| GK190-E |

Rc 2" |

Rc 2 1 or 2" |

360 |

428 |

| GK250-E |

Rc 2" |

Rc 2 1 or 2" |

450 |

600 |

| GK320-E |

Rc 2" |

Rc 2 1 or 2" |

550 |

737 |

| JK190-E |

Rc 2 1 or 2" |

80 |

550 |

737 |

| JK250-E |

Rc 2 1 or 2" |

80 |

700 |

938 |

| JK320-E |

Rc 2 1 or 2" |

80 |

850 |

1140 |

| PK190-E |

Rc3" |

100 |

700 |

938 |

| PK320-E |

Rc3" |

100 |

950 |

1273 |

| PK350-E |

Rc3" |

100 |

1200 |

1608 |

| PK400-E |

Rc3" |

100 |

1400 |

1876 |

1. Tube diameter: Using a small tube diameter makes the heat exchanger both economical and compact. However, it is more likely for the heat exchanger to foul up faster and the small size makes

mechanical cleaning of the fouling difficult. To prevail over the fouling and cleaning problems, larger tube diameters can be used. Thus to determine the tube diameter, the available space, cost and

the fouling nature of the fluids must be considered.

2. Tube thickness: The thickness of the wall of the tubes is usually determined to ensure:

a.There is enough room for corrosion

b.That flow-induced vibration has resistance

c.Axial strength

d.Availability of spare parts

e.Hoop strength (to withstand internal tube pressure)

f.Buckling strength (to withstand overpressure in the shell)

3.Tube length: heat exchangers are usually cheaper when they have a smaller shell diameter and a long tube length. Thus, typically there is an aim to make the heat exchanger as long as physically possible whilst not exceeding production capabilities. However, there are many limitations for this, including the space available at the site where it is going to be used and the need to ensure that there are tubes available in lengths that are twice the required length (so that the tubes can be withdrawn and replaced). Also, it has to be remembered that long, thin tubes are difficult to take out and replace.

4.Tube pitch: when designing the tubes, it is practical to ensure that the tube pitch (i.e., the centre-centre distance of adjoining tubes) is not less than 1.25 times the tubes' outside diameter. A larger tube pitch leads to a larger overall shell diameter which leads to a more expensive heat exchanger.

5.Tube corrugation: this type of tubes, mainly used for the inner tubes, increases the turbulence of the fluids and the effect is very important in the heat transfer giving a better performance.

6.Tube Layout: refers to how tubes are positioned within the shell. There are four main types of tube layout, which are, triangular (30°), rotated triangular (60°), square (90°) and rotated square(45°). The triangular patterns are employed to give greater heat transfer as they force the fluid to flow in a more turbulent fashion around the piping. Square patterns are employed where high fouling is experienced and cleaning is more regular.

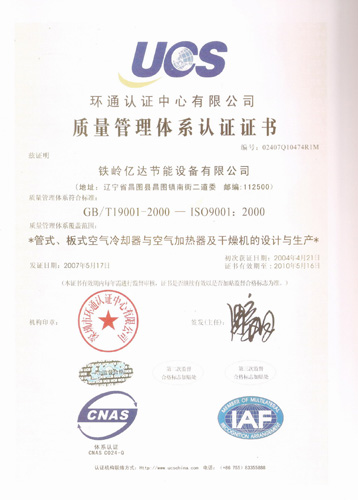

Certificate: